Products

Product Introduction

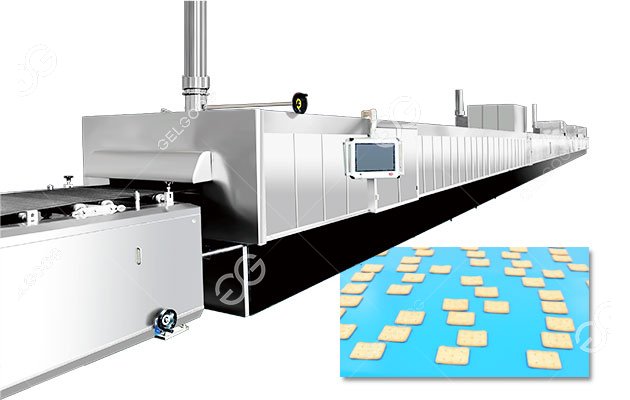

The biscuit factory oven is a multipurpose tunnel oven that can be used to bake a variety of biscuits. It supports electric heating and gas heating, allowing factories to flexibly choose energy based on cost or availability.

This oven is designed for industrial factories. Whether you want to bake hard biscuits, soft biscuits, crackers or gluten-free snacks, it provides even heat distribution and precise temperature control.

Features of Biscuit Tunnel Oven

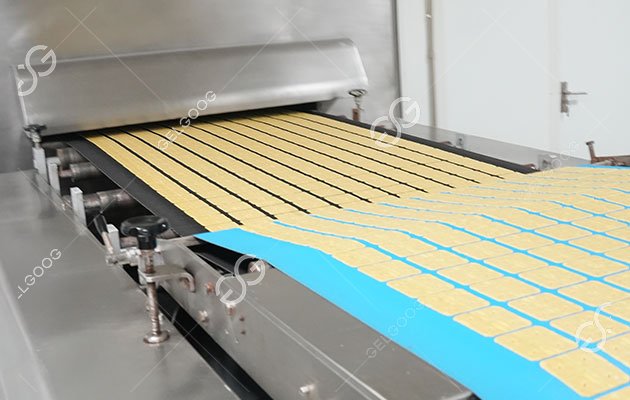

- High efficiency and stable production efficiency: Tunnel ovens can produce continuously, and uniform baking and conveying are completed through the relative movement of conveyor belt chains, steel belts or mesh belts and heating elements. In addition, the biscuit oven is equipped with a variable frequency speed control device, which can adjust the baking time and speed according to the type of biscuits.

- Accurate temperature control: Biscuit factory ovens are usually divided into multiple independent temperature zones, each with an independent heating and temperature control system. The PLC control system is used to pre-store multiple sets of parameters. The operator only needs to call the corresponding settings to achieve automatic operation and ensure stable and consistent biscuit quality.

- Uniform heating effect: The oven is equipped with a hot air circulation device, which uses a fan to circulate the hot air evenly in the biscuit oven machine. In addition, the heating elements are reasonably arranged. For example, the quartz electric heating tube can convert the light energy radiated by the electric heating wire into far-infrared radiation to ensure uniform heat distribution.

- Diverse product adaptability: Biscuit baking tunnel oven is designed to accommodate diverse production needs, offering the flexibility to bake various biscuit types, such as crispy and tough biscuits, by adjusting parameters like temperature and time. Additionally, the oven's dimensions, including length and width, can be customized to suit specific production sites and output requirements.

- Safety and environmental protection features: The gas biscuit oven is equipped with automatic control, automatic ignition, automatic detection, automatic alarm and other safety protection devices. Some industrial biscuit tunnel oven adopt energy-saving design and efficient combustion technology, such as equipped with heat recovery system to reduce energy consumption, which meets environmental protection requirements.

Advantages of Biscuit Factory Oven

- High - efficiency and stable production: Biscuit tunnel ovens use a continuous production mode, enabling efficient baking. Advanced models feature variable - frequency speed regulation for customized production efficiency.

- Precise temperature control: They are equipped with multiple independent temperature - controlled zones and a PLC - based system for automated operation and consistent quality.

- Uniform heating: With a rational heating - element layout and thermal - wind circulation devices, they ensure uniform heat distribution for high - quality baking.

- Diverse product adaptability:Capable of baking various biscuit types, these biscuit oven machine can be customized in size to meet different production needs.

- Safety and environmental protection: Automated safety features, efficient combustion technology, and heat - recovery systems ensure energy saving and emission reduction.

- Easy to maintain and clean: This industrial biscuit factory oven is made of stainless steel and detachable, it is easy to access internal components and simplifies daily maintenance and cleaning.

Technical Data

| Dimensions(L*W*H) | 21000*2280*2180MM |

| Total Calories | 224280Caloric(kcal/h) |

| Air Consumption(Gas Consumption) | 0.9m³/m |

| Power | 2HP |

| Voltage | 380V |

| Size of Baking Plate | 40*60CM |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language