Products

Product Introduction

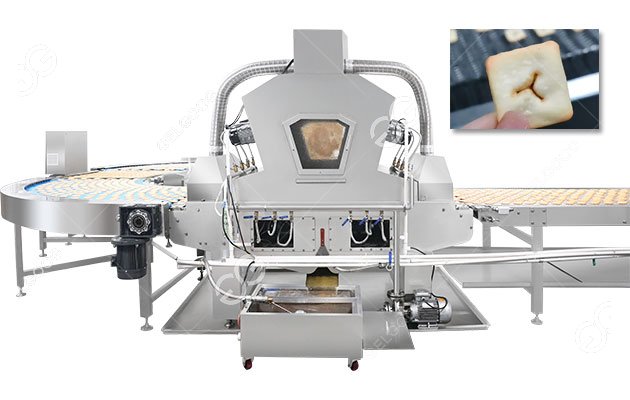

This biscuit oil sprayer machine delivers precise, uniform coatings for biscuits and snacks. Designed for high-volume production, it combines durability and oil-saving features to minimize waste.

This next-gen oil sprayer focuses on eco-friendly performance and smart automation. Unlike traditional systems, it combines ultra-hygienic design with AI-driven adjustments to meet strict food safety norms.

Features of Biscuit Oil Sprayer Machine

- Dual-Sided Spray System: Equipped with top and bottom nozzles, it coats both surfaces of biscuits simultaneously. Adjustable pressure settings handle delicate wafers or thick crackers without breakage.

- Smart Temperature Control: Integrated heating maintains oil at 45°C–65°C, ensuring optimal viscosity. Prevents cold oil clogs and guarantees smooth, even coverage.

- Rapid Oil Change Function: Switch between oil types (e.g., sunflower, butter) in 90 seconds. Sealed tanks prevent flavor mixing, ideal for allergen-free production lines.

- Auto-Adjust Conveyor: Infrared sensors detect biscuit sizes and adjust conveyor speed automatically. Eliminates manual tuning for different product batches.

- Self-Cleaning Nozzles: Activate a 5-minute cleaning cycle post-operation. This biscuit oil spraying machine Removes residue without disassembly, reducing downtime between shifts.

Biscuit Spraying Process in Factory

- Preparation: Load oil into temperature-controlled tanks. Select the biscuit type on the touchscreen interface.

- Spraying Phase: Biscuits move through the conveyor, where dual nozzles apply oil evenly. Sensors ensure each piece receives the programmed amount.

- Recycling & Maintenance: Excess oil flows into a filtration system for reuse. Post-shift, initiate self-cleaning to prepare for the next batch.

Advantages of Biscuit Oil Spraying Machine

- 50% Less Oil Waste: Targeted spraying and drip recycling cut oil usage by half compared to traditional methods. Reduces costs and environmental impact.

- 24/7 Durability: Stainless steel construction resists corrosion, heat, and moisture. Built for continuous operation in demanding factory environments.

- Plug-and-Play Setup: Pre-programmed modes for common biscuit types (e.g., digestives, shortbread). No technical expertise needed—operational within 15 minutes.

- Food Safety Certified: This automatic oil sprayer machine meets global standards (ISO 22000, HACCP). Smooth surfaces and enclosed systems prevent bacterial growth for audit-ready hygiene.

- Scalable Production: Processes 100–1200 kg of biscuits per hour. Easily integrates with existing packaging or cooling systems for end-to-end automation.

Why Factories Love Biscuit Oil Sprayer Machine

- Zero Cross-Contamination: Sealed oil circuits prevent flavor mixing—ideal for allergen-free lines (nuts, gluten).

- 15-Minute Deep Clean: All parts detach without tools; dishwasher-safe trays save labor.

- Silent Operation: 55dB noise level vs. 75dB in older models—no more ear protection needed.

- Healthier Recipes: Spray olive oil or vitamin-enriched blends on low-fat crackers.

- Flavor Layering: This machine add alternating sprays (e.g., butter oil + salt mist) for gourmet textures.

- Frozen Snacks: Works in chilled zones (-5°C) for oil-coating protein bars or granola pre-freezing.

Technical Data

| Name | Oil Sprayer Machine |

| Material | Stainless steel 304 |

| Control mode | PLC |

| Power | 9KW |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language