How to Start a Biscuit Manufacturing Business with Machine

How to start a biscuit manufacturing business with an industrial machine? Compared with manual work, this is a very time-saving and labor-saving production method to start biscuit business.

Starting a biscuit making business with a biscuit plant involves several key steps and considerations. Here's a comprehensive guide to starting your business:

1. Comprehensive Market Analysis:

Embark on an extensive exploration of the biscuit market to gain insights into consumer trends, demand dynamics, competitive landscape, and untapped market opportunities. It's vital to pinpoint the specific preferences in flavor, packaging design, and price points of your intended customer base. This understanding is key to customizing your product to meet the nuanced needs and expectations of your target audience effectively.

2. Detailed Business Planning:

Develop an exhaustive business plan encompassing your business objectives, target market segmentation, delineated marketing strategies, budget allocation, equipment requirements, and comprehensive financial projections. This blueprint will serve as a guiding document for your business operations.

3. Legal Compliance and Formalities:

Prioritize the legal aspects by registering your biscuit manufacturing business entity appropriately. Obtain all necessary licenses and certifications required for food production and distribution. Ensuring strict adherence to health, safety, and food quality standards is paramount in the food manufacturing industry.

4. Location and Infrastructure:

Choose a suitable location for your biscuit manufacturing plant with adequate space for production, storage, and distribution. Ensure access to utilities like water, electricity, and transportation.

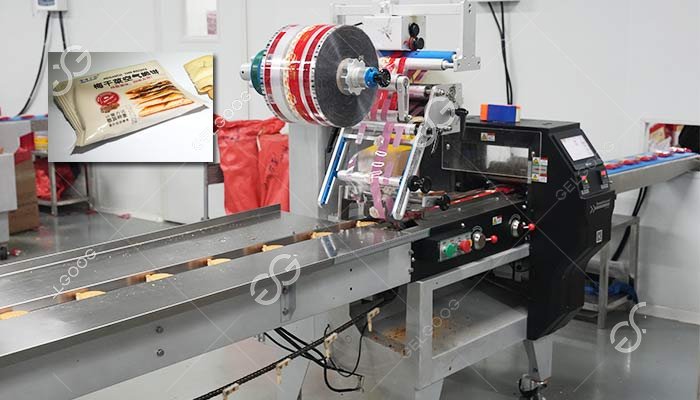

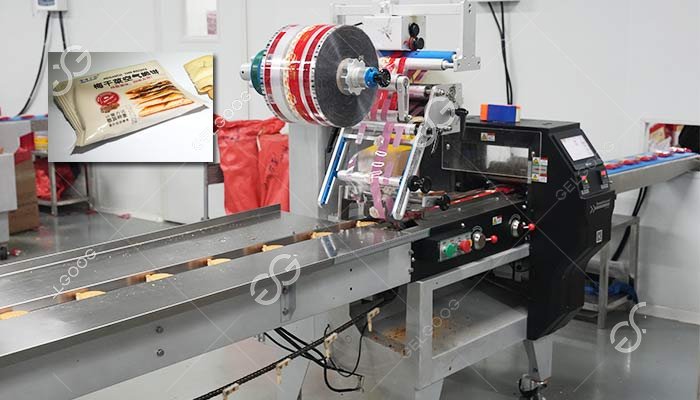

5. Procure Equipment:

Invest in high-quality biscuit manufacturing machinery like dough mixers, dough sheeters, ovens, and packaging equipment. Consider factors like production capacity, efficiency, and automation capabilities.

6. Recipe Development:

Develop or procure unique and high-quality biscuit recipes that align with consumer preferences. Experiment with flavors, textures, and ingredients to create a standout product.

7. Raw Material Sourcing:

Establish relationships with reliable suppliers for high-quality raw materials like flour, sugar, flavorings, and packaging materials. Ensure a consistent supply chain for uninterrupted production.

8. Biscuit Production Process:

Train your staff on operating biscuit machinery, maintaining hygiene standards, and following strict quality control measures throughout the production process. Implement efficient workflows to optimize production of biscuits.

9. Branding and Packaging:

Design an appealing brand logo, packaging, and labeling that resonate with your target audience. Invest in attractive and informative packaging for biscuit to enhance shelf appeal.

10. Marketing and Distribution:

Implement a robust marketing strategy that spans both online and offline channels. Use social media, website and partnerships with distributors to effectively reach your target market and reach more cookie wholesalers and consumers.

11. Quality Control and Testing:

Regular quality inspections of biscuit plant and biscuit product testing are conducted to ensure quality consistency and compliance with quality standards. Ask for consumer feedback to improve your product.

Starting a biscuit manufacturing business with a machine can efficiently complete the production of biscuits and ensure quality. If you want to start a biscuit business or plan to build a biscuit factory, please feel free to contact us, our company provides a complete set of biscuit solution services.

Email: lisa@gelgoog.com

Whatsapp/Wechat: +8615515571373

Starting a biscuit manufacturing business with a machine can efficiently complete the production of biscuits and ensure quality. If you want to start a biscuit business or plan to build a biscuit factory, please feel free to contact us, our company provides a complete set of biscuit solution services.

Email: lisa@gelgoog.com

Whatsapp/Wechat: +8615515571373

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language