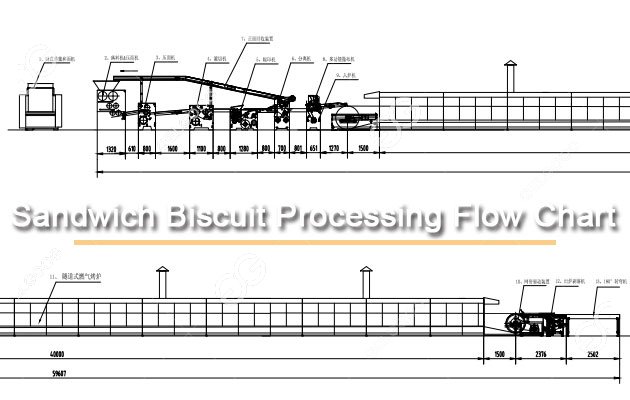

Automatic Sandwich Biscuit Processing Flow Chart

The sandwich biscuit processing process is simple. The automatic biscuit production line developed by our company can automatically complete raw materials to biscuit forming.

Flow Chart of Sandwich Biscuits Production Process is as follows:

Prepare Ingredients — Mixing the Dough — Sandwich Biscuits Forming — Baking — Oil Spraying — Sandwiching — Cooling — Biscuits Arranging — Biscuits Packing.

Main Equipment:

① Dough mixer is a machine that mixes flour with water or other ingredients into dough. It is suitable for making various pastries, biscuits, bread, steamed buns and other doughs.

② Hard biscuit forming machine: put the mixed flour into the machine, and roll it to form a biscuit embryo, and put it into the oven to make various hard biscuits.

③ Soft biscuit forming machine: puts the mixed dough into the machine, presses the skin through three rollers, and then cuts into biscuit embryos by a roller cutting mold once, enters the oven, and bakes soft biscuits.

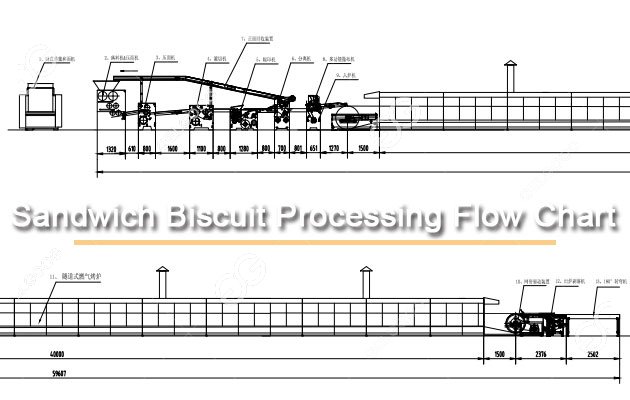

④ Biscuit tunnel oven: heating by electricity or gas, controlled by different temperature zones, and the temperature of each temperature zone can be set. The temperature in the temperature zone is uniform, and the insulation material is used, which has good heat insulation performance. Flexible operation, high safety performance, suitable for baking all kinds of biscuits.

⑤Oil spraying machine: After baking, spray various delicious and fragrant food oils, refined oils, sugar water, etc. on the surface of the biscuits. The surface of the biscuit is bright, which improves the appearance and taste of the biscuit.

⑥Sandwich machine: drops cream or other sandwiches to the biscuits on the conveyor belt, and then covers with a biscuit, which is slightly pressed to make the two biscuits and the sandwich stick together.

⑦Choose a packaging machine according to the shape and needs of biscuits: pillow packaging machine, automatic weighing packaging machine, etc. The biscuits are packaged for good quality and extended shelf life.

④ Biscuit tunnel oven: heating by electricity or gas, controlled by different temperature zones, and the temperature of each temperature zone can be set. The temperature in the temperature zone is uniform, and the insulation material is used, which has good heat insulation performance. Flexible operation, high safety performance, suitable for baking all kinds of biscuits.

⑤Oil spraying machine: After baking, spray various delicious and fragrant food oils, refined oils, sugar water, etc. on the surface of the biscuits. The surface of the biscuit is bright, which improves the appearance and taste of the biscuit.

⑥Sandwich machine: drops cream or other sandwiches to the biscuits on the conveyor belt, and then covers with a biscuit, which is slightly pressed to make the two biscuits and the sandwich stick together.

⑦Choose a packaging machine according to the shape and needs of biscuits: pillow packaging machine, automatic weighing packaging machine, etc. The biscuits are packaged for good quality and extended shelf life.

The entire sandwich biscuit process is automated, which improves biscuit production efficiency and saves labor costs. And one machine is multi-purpose, different biscuits can be made by replacing several devices. If you want to know more about the biscuit processing process flow chart, please feel free to contact us.

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language