Products

Product Introduction

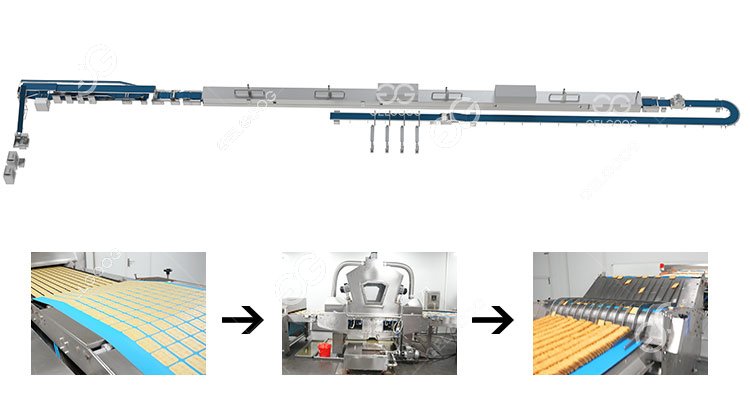

The biscuit factory production line is an automated system that can produce large quantities of biscuits per hour. The whole process is efficient and is the preferred equipment for the biscuit industry.

It includes multiple stages, each of which involves different mechanical equipment and process flows. The main ones are: preparing raw materials, mixing dough, pressing dough, biscuit molding, biscuit baking, biscuit oil spraying, biscuit cooling, biscuit packaging, etc.

Components Of Industrial Biscuit Production Line

- Dough mixer: used to mix flour, sugar, oil, dairy products, egg products, leavening agents and salt into dough.

- Forming machine: press the cut dough into a certain shape (determined by the mold) to initially form the shape of the biscuit.

- Tunnel baking oven: used to bake biscuits at high temperature to make the biscuits cooked and add flavor.

- Oil sprayer: spray a layer of oil mist on the surface of the biscuits to make the biscuits better in color and flavor.

- Turning machine: if the factory space is sufficient, this equipment may not be needed. It is used to turn in the production line.

- Cooling conveyor: quickly cool the baked biscuits to prevent the biscuits from becoming soft after packaging and extend the shelf life.

- Biscuit sorting machine: sort the baked biscuits and remove unqualified products.

- Packaging machine: Automatically completes the packaging of biscuits, including bag making, bagging and sealing.

Automation System Of Biscuit Factory Production Line

The machines are usually designed with high efficiency and flexibility in mind. The application of automation technology enables the production line to run 24 hours a day without interruption, while reducing manual intervention, improving production efficiency and consistency of product quality. Modern production lines usually include the following key automation links:

- Automatic batching system: The equipment accurately controls the proportion of each raw material to ensure the consistency of the formula of each batch of biscuits.

- Automatic conveying system: Seamlessly convey the dough and finished biscuits on the industrial biscuit production line to reduce manual handling.

- Automatic detection and rejection system: Detect the quality of biscuits, automatically reject unqualified products, and ensure the quality of the final product.

- Data monitoring system: Real-time monitoring of the operating status of the production line, collecting data for quality control and production optimization.

Video of Biscuit Processing Line

As a professional biscuit factory production line supplier, we play an important role in the global food industry. Our production line is capable of mass-producing various types of biscuits to meet the needs of different markets.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language