Products

Product Introduction

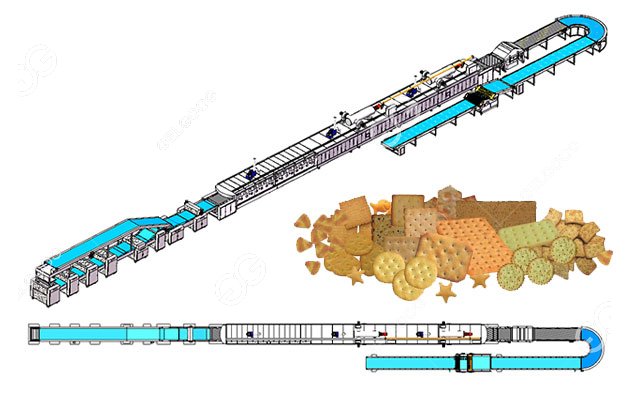

The GG-BG400 model automatic biscuit making machine is suitable for small scale biscuit processing. The manufacturer also developed large scale production lines for biscuits, with an output of 1250 kg per hour.

It is suitable for some biscuit suppliers who want to develop new products or upgrade old equipment. The complete include biscuit forming machine, tunnel oven, cooling line, packing machine, etc.

Automatic Biscuit Processing Flow: flour and water are evenly mixed into dough → molds form biscuits of different styles → enter the tunnel oven to bake biscuits → baked golden biscuits are conveyed and cooled by conveyor belt → spray oil on the surface of biscuits after leaving the oven → use turning machine saves the workshop space → arranges the biscuits neatly → packs them into bags.

Features of Automatic Biscuit Making Machine

- The machine has a wide range of applications, and there are various biscuit styles can be produced. Biscuit molds can be designed and customized according to requirements.

- The material of this biscuit machine is excellent and durable, and all parts in contact with food are made of stainless steel materials.

- The overall design of the small scale biscuit making machine is novel, compact in structure, high in automation and high in work efficiency.

- It is suitable for biscuit manufacturers with a small, medium and large output of 100-1250 kg per hour, the biscuit machine is easy to operate and easy to use.

- The automatic biscuit machine line operates stably, and the biscuits production qualification rate can reach more than 95%.

- All parts are manufactured by big brands and precision-made, which are more stable and safe during use.

Small Scale Biscuit Making Machine Video

Automatic Biscuit Making Machine Operate

Operating an automatic biscuit machine involves several steps. Below are the general steps to operate such a machine:- Preparation: Before you start, ensure that the machine is clean and in good working condition.

- Machine Setup: Depending on the specific type and model of small scale biscuit making machine you have, there may be different setup procedures. You can refer to the manual to set up the machine.

- Program Selection: Select the appropriate program for the type of biscuits you want to make, such as setting parameters such as dough mixing time, biscuit baking temperature and time.

- Monitor the process: Keep an eye on the operation of the machine to ensure everything is running smoothly. Check the consistency of the dough, biscuit baking, arranging and packaging.

- Cleaning: After use, clean the biscuit machine thoroughly according to the manufacturer's instructions to ensure it remains in good working condition.

The biscuit making machine produced by the factory can be used to produce all kinds of hard and soft biscuits, and the machine is durable. From feeding calendering, molding, waste recycling, baking, oil spraying, cooling, packaging to complete fully automatically at one time. The factory can plan venues, biscuit plans, etc. according to user needs.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language