Products

Product Introduction

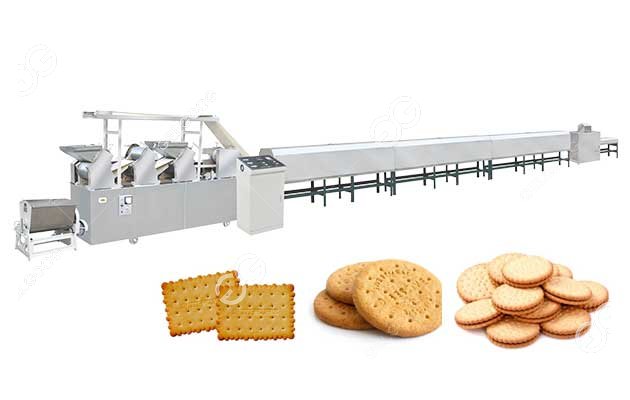

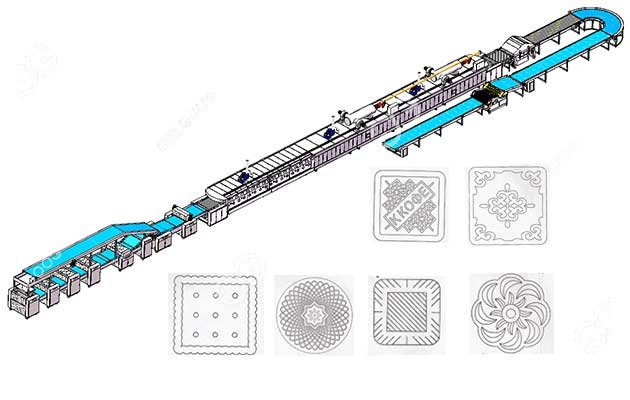

The complete biscuit manufacturing plant can be automated from mixing, biscuit forming, baking, cooling to packaging. The output is varied, ranging from 80-1400 kg/h, and there are many molds, which can produce different styles of biscuits.

Biscuit production is a complex process that requires specialized equipment to ensure a high-quality product. The industrial biscuit line is designed to make the operation easier and more efficient for biscuit factories.

Biscuit production is a complex process that requires specialized equipment to ensure a high-quality product. The industrial biscuit line is designed to make the operation easier and more efficient for biscuit factories.

Function of Biscuit Production Plant

This line is used to automate the production process of biscuits. The machine line performs several functions such as mixing, shaping, baking, cooling, and packaging. The device makes it possible to produce a large number of biscuits and cookies in a short time.

Features of Complete Biscuit Manufacturing Plant

- Good Quality Production: Biscuits are consistent in quality, shape, and size, this machine enabling the production of biscuits that meet industry standards.

- Widely Used: Biscuit plant can produce various types of biscuits such as cream-filled, sandwich, and plain biscuits. It is customizable to meet the specific needs of the manufacturer.

- High Efficiency: This production line is produced to consume less energy, making it cost-effective for manufacturers.

- Easy to Operate: Biscuit production line is easy to operate, and the manufacturers can train their staff to use it effectively.

- Automated: This industrial machine is fully automated, reducing the need for manual labor and increasing production efficiency.

Operation Steps of Complete Biscuit Plant

- Mixing: The ingredients are mixed in the mixing machine to form a dough.

- Shaping: The dough is then shaped by the biscuit forming machine. This machine can shape the dough into various shapes such as round, square, or rectangular.

- Baking: The shaped dough is then baked in the tunnel oven. The oven temperature and humidity are maintained at optimal levels to produce high-quality biscuits.

- Cooling: The biscuits are then cooled in the cooling conveyor. The cooling process helps to solidify the biscuits and prevent breakage.

- Packaging: The finished biscuits are then packaged in the packaging machine. It can package the biscuits in various packaging materials such as boxes, bags.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language