Products

Product Introduction

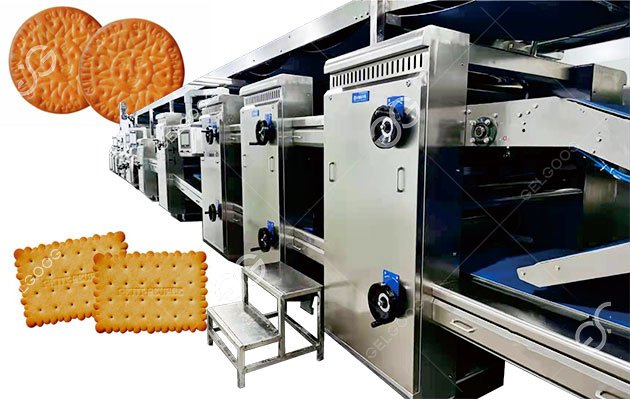

The hard biscuit production line developed by Gelgoog can not only produce hard biscuits with consistent quality and various varieties, but also provide various production capacity specifications to meet market demand.

This biscuit line is a complete professional biscuit processing equipment, widely used to produce different kinds of hard biscuits. Not only that, this company can also customize your needs.

Advantages of Hard Biscuit Machine

- Various shapes of hard biscuits can be produced on one set of production line, saving investment costs.

- The unique double-layer core-filled biscuits can be well combined with the local flavor diet to form a new flavor of biscuits.

- The hard biscuit line has the quality of first-tier brands, but only two-thirds of the price of first-tier brands, which is cost-effective.

- There are various heating methods for the biscuit oven. The oven with the GG-BG1000 model can use electric heating, gas heating, and diesel heating.

- The whole hard biscuit production line runs stably and is easy to operate, and the qualified rate of production can reach more than 95%.

- Gelgoog has the planning ability of the whole line plan, and can provide all-round production guidance. Including the planning and layout of the production line plant; research and development of corresponding product formulas as required; training of operators.

- The most important thing is that gelgoog company can be upgraded for your existing hard biscuit making machine to meet your needs.

The Core Equipment of Hard Biscuit Production Line

- Horizontal Dough Mixer: The mixing machine that mix flour, water and other ingredients into dough. Usually used in conjunction with pressing equipment, it is one of the essential equipment in automatic hard biscuit line.

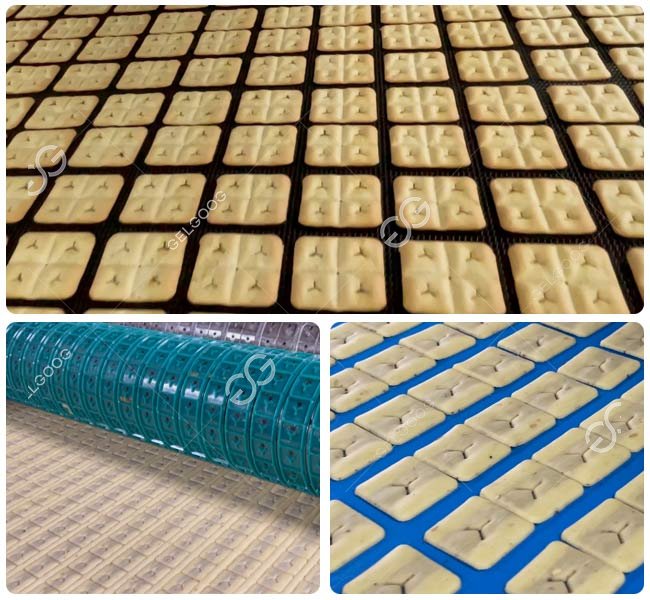

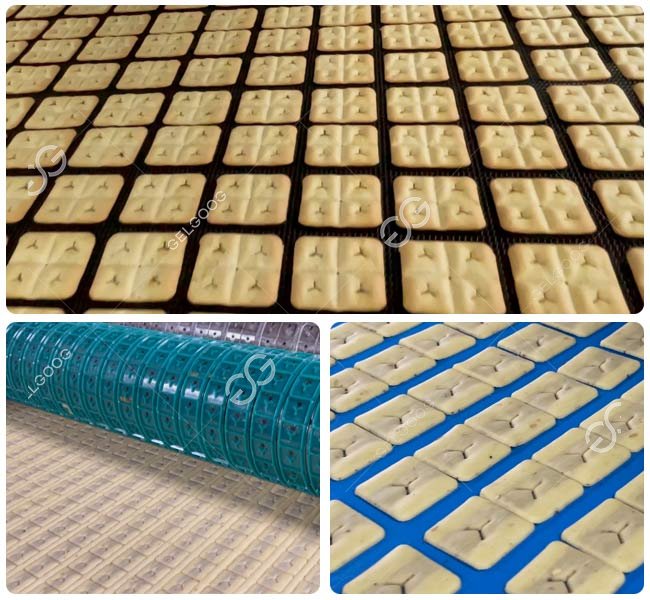

- Dough Pressing Machine: Roll the dough to the required thickness, and at the same time make the texture of the dough more uniform and tougher. Data such as the thickness and speed of the dough are displayed on the display in real time, which is convenient for the operator to adjust as needed.

- Biscuit Forming Machine: Dough sheets with uniform thickness are cut into forming molds by rollers to complete printing, forming, demoulding and other operations. This equipment is used for forming different styles of hard biscuits. The distance between the roller cutting die and the rubber roller and the speed can be adjusted.

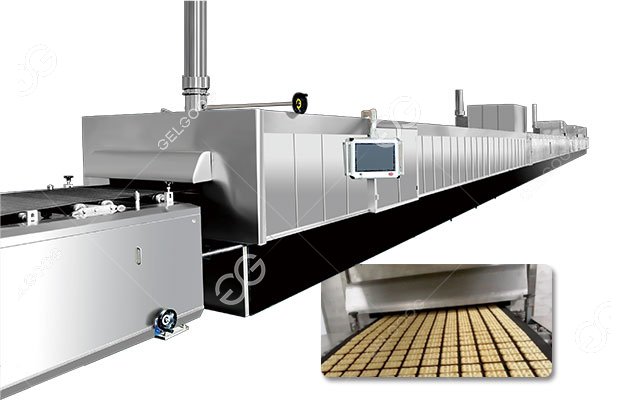

- Tunnel Oven: The biscuits are baked in an oven tens of meters away, and undergo precise temperature and humidity control in different intervals. This baking process is critical to achieving the desired texture, color and flavor of the hard biscuit. The power, length and width of the oven can also be customized according to your actual needs.

- Cooling Line and Packaging Machine: After baking, the hard biscuits move along a long conveyor belt to cool and stabilize. Cool to a suitable temperature, and pack equal amounts of biscuits into bags to prolong the storage time of biscuits.

Video of Hard Biscuit Machinery

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language