Products

Product Introduction

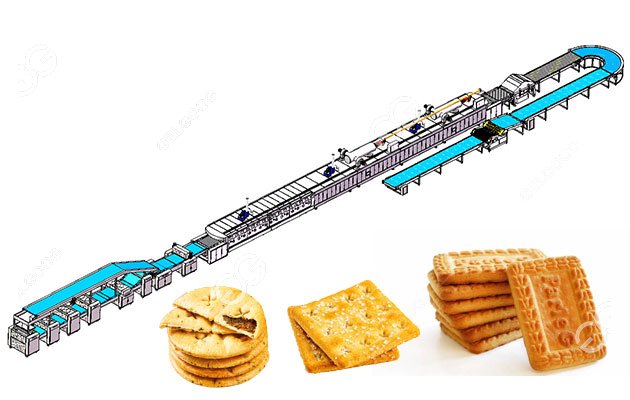

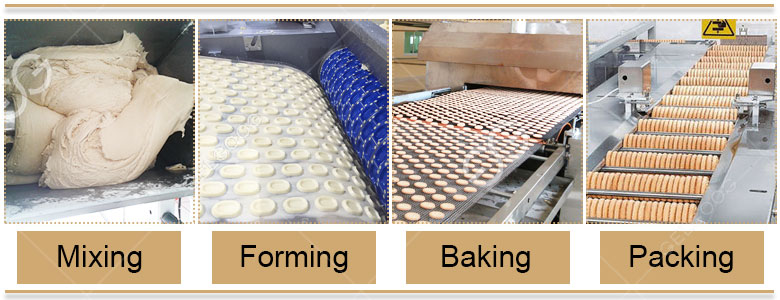

The hard and soft biscuit production line can produce different kinds of soft biscuits and hard biscuit according to different process requirements. It is fully automated from feeding, pressing, forming, baking, oil spraying, cooling to packaging.

This production line is a complete and highly automated industrial equipment used for the large scale manufacturing of hard biscuits, soft biscuits. One hour's capacity is 500-1200kilograms.

Finished Biscuits Display

In order to meet the needs of different users, the automatic biscuit production line factory provides users with hundreds of molds and dozens of process formulas. By changing the molds and process formulas, various biscuits on the market can be produced. Such as butter biscuits, sandwich biscuits, soda biscuits, animal biscuits, letter biscuits, vegetable biscuits, etc. The picture below shows our common biscuits.

Technical Parameters of Hard and Soft Biscuit Production Line

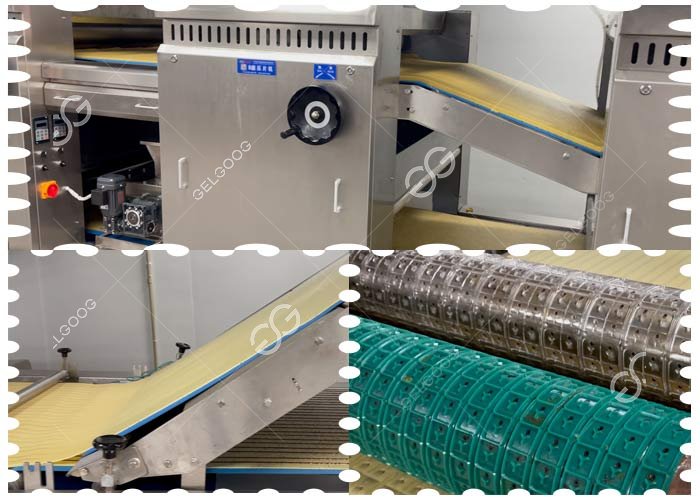

- Lamination method: cut-off lamination, number of lamination layers: 4-12 layers.

- Cut-off method: electric, the cut-off position is tracked by an electric eye.

- This fully automatic biscuit production line uses 304 stainless steel where the pallet and food can touch.

- The whole machine is operated in linkage, adopts frequency converter and independent drive by single motor.

- The pressure regulating handle of the band meter can produce all kinds of dough thickness required.

Let's watch this video below to understand how the biscuit line works?

Advantages of Hard and Soft Biscuit Production Line

- The factory has a library of more than 100 kinds of biscuit crafts, which makes the production of biscuits easier. If you have a unique formula, we can also meet your needs.

- Large-capacity and high-standard equipment can replace most first-line brand products. It is durable and has a long service life.

- The production line manufacturer has the service capability of HACCP standard equipment layout planning.

- Economical and cost-effective. Compared with biscuit equipment of the same quality, the price of this manufacturer is more affordable.

- The biscuit is well formed, the yield of the finished product is over 95%, and the color and taste of the finished product are good.

- The mold can be customized according to the needs of customers, and the same manufacturer can realize it, without the need to find additional manufacturers.

- The whole biscuit line is automatic production, basically no staff maintenance is required in the hard and soft biscuit processing process, and there are very few operators.

- The molds can be easily changed, so that the production of hard and soft biscuits in various shapes and sizes can be realized.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language