Products

Product Introduction

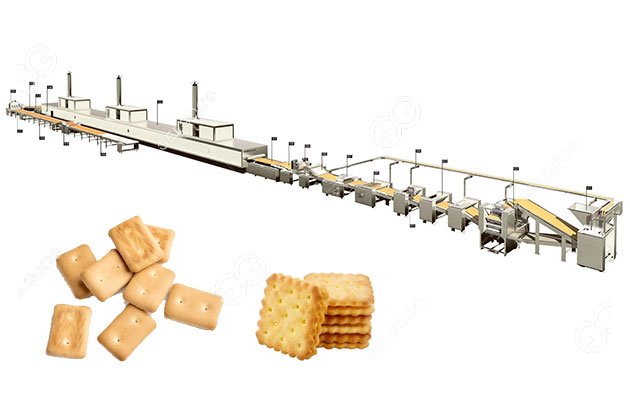

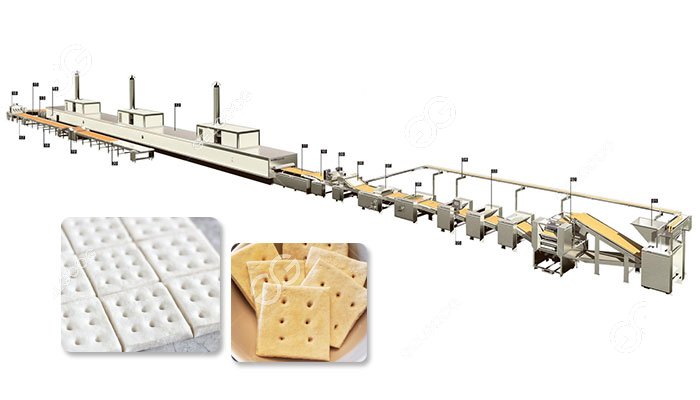

The automatic hard tack biscuit production line combines advanced technology and precision engineering to deliver high-quality hard tack biscuits at an accelerated rate.

In the modern era, automation plays a pivotal role in enhancing efficiency and productivity in various industries. The food industry is no exception, where automation has revolutionized the manufacturing process.

Features of Hard Tack Production Line

- Versatility: This hard tack machine is designed to accommodate various hard tack biscuit sizes and shapes, providing manufacturers with flexibility to cater to diverse consumer preferences. It can produce round, square, rectangular, or even custom-shaped hard tack biscuits with ease.

- Efficient Dough Processing: This machine excels in dough processing, employing a combination of mixing, kneading, and shaping techniques to create the great biscuit dough consistency. It ensures thorough and consistent mixing of ingredients, resulting in uniform texture and taste across all hardtack biscuits.

- Precise Cutting and Molding: Hardtack biscuit production line incorporates advanced cutting and molding mechanisms to shape the hard tack biscuit dough accurately. This precision eliminates irregularities, ensuring uniformity in size and shape throughout the production process.

- Optimal Baking Conditions: With carefully designed heat distribution and control systems, the machine ensures the hard tack biscuits are baked to perfection. It maintains consistent temperatures and airflow, guaranteeing even baking and preventing overcooking or undercooking.

- Easy Maintenance and Cleaning: The hard tack biscuit line is designed with accessibility in mind, making maintenance and cleaning procedures straightforward. This feature reduces downtime and enhances operational efficiency.

- Precision Engineering: The machine is crafted with meticulous attention to detail, utilizing high-quality materials and advanced manufacturing techniques. This ensures the machine's durability, stability, and reliable performance, even under demanding production conditions.

Video of Hardtack Biscuit Production Line

Processing Flow of the Hard tack Production Line

- Ingredient Mixing: With the precise blending of ingredients, including flour, sugar, fat, and flavorings, in the mixing section of the machine. This ensures a homogeneous dough mixture.

- Dough Shaping: The dough is then fed into the shaping section of the machine, where it is rolled and molded into the desired biscuit shapes.

- Cutting and Patterning: The shaped dough is cut and patterned by the machine, accurately creating the final hardtack biscuit design.

- Baking: The cut dough is then transferred to the baking section of the hardtack biscuit line, where it undergoes the baking process at optimized temperatures and times.

- Cooling and Packaging: After baking, the biscuits are cooled to room temperature, allowing them to harden. Subsequently, they are packaged and prepared for distribution.

The automatic hard tack biscuit production line has numerous advantages, including increased productivity, consistent quality, reduced labor costs, and improved safety standards. Our company provides users with complete biscuit processing solutions, from A to Z.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language