Products

Product Introduction

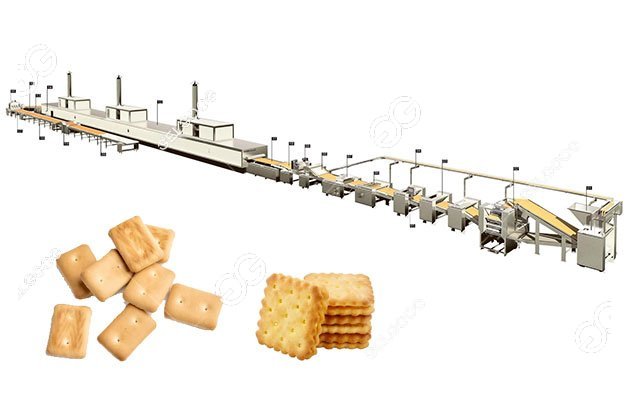

The hello panda cracker production line is a specialized manufacturing setup designed for the production of the popular Hello Panda filled crackers. The entire line is easy to operate and highly efficient.

This cracker renowned for its distinctive flavor and cute panda design, is produced on a line that embodies cutting-edge technology and rigorous quality control. This setup guarantees the creation of premium, delightful crackers that captivate a broad audience, enchanting both children and adults alike.

A significant achievement was realized with the introduction of the hello panda cracker production line at a prominent snack manufacturing firm in Asia. Faced with the challenge of fulfilling escalating demands for Hello Panda crackers without compromising on quality, the company experienced a dramatic turnaround upon integrating this sophisticated production line. The efficiency of production soared by more than 50%, enabling the company to amplify its production scale without incurring extra labor expenses.

Features of Hello Panda Cracker Production Line

- Advanced Dough Mixing Technology: Ensures uniform texture and flavor of the panda cracker base.

- Precision Filling System: Delivers the perfect amount of filling, whether it be chocolate, strawberry, or other flavors, without compromising the cracker's shape.

- High-Speed Printing and Embossing: Allows for the iconic panda imprint on each cracker with consistency and speed.

- Automated Sealing and Packaging: Ensures that the crackers are airtight and preserved for freshness.

- Integrated Quality Control: Advanced sensors and monitoring systems continuously check the product quality throughout the production process.

Hello Panda Biscuit Production Video

Hello Panda Biscuit Production Line Advantages

- Efficiency in Production: The automated systems significantly increase productivity while maintaining the same high quality and meeting different needs.

- Product Quality Consistency: With advanced technology, each hello panda cracker maintains consistent taste and texture, increasing consumer satisfaction.

- Product Variety Flexibility: The hello panda cracker line is adaptable, capable of manufacturing a range of flavors and fillings. This versatility allows it to meet diverse market tastes and preferences.

- Minimized Material Waste: The precision of automation in the biscuit production line leads to reduced waste of materials, enhancing cost efficiency and promoting eco-friendly practices.

- Decreased Labor Expenses: The automation of the production process diminishes the reliance on manual labor, thereby cutting down on overall production expenses.

A significant achievement was realized with the introduction of the hello panda cracker production line at a prominent snack manufacturing firm in Asia. Faced with the challenge of fulfilling escalating demands for Hello Panda crackers without compromising on quality, the company experienced a dramatic turnaround upon integrating this sophisticated production line. The efficiency of production soared by more than 50%, enabling the company to amplify its production scale without incurring extra labor expenses.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language