Products

Product Introduction

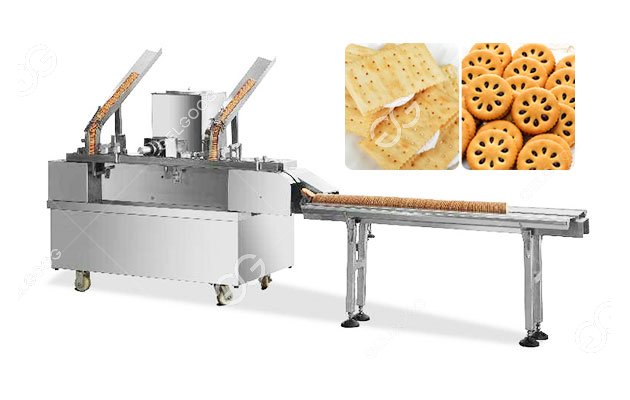

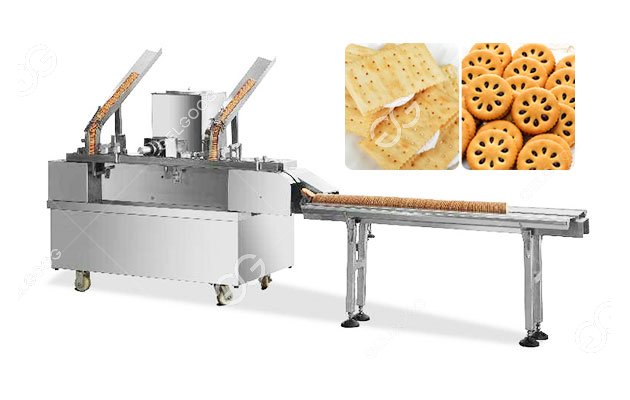

The sandwich biscuit making machine is mainly suitable for the production of sandwich biscuits, such as 2+1 or 3+2 sandwich biscuits, which can be selected according to customer requirements. It can be filled with cream, chocolate, jam, cheese and so on.

Application:

Main Performance of Cream Biscuit Making Machine

1. The main components of the whole machine are made of stainless steel, which meets the sanitary standards.

2. It adopts color touch screen control, easy to use and accurate filling amount.

3. High-precision intelligent PLC control, stable and reliable machine performance.

4. The thickness of the material level is adjusted by electric control, and the positioning is more accurate.

5. The automatic stacking function of sandwich biscuits can be selected to meet customer requirements.

6. The mechanical design is more flexible, each link can be operated independently, and the operation is more convenient.

Here is a Working Video of Sandwich Biscuit Machine

Here is a Working Video of Sandwich Biscuit Machine

Features of Sandwich Biscuit Machine

1. Independent frequency inverter for control and regulation.

2. 2.65 meters long conveyor belt to feed biscuits.

3. Siemens inverter and PLC touch screen and Schneider Electric.

4. Delta servo motor and gear box.

5. The double coat on the cream water tank is heated.

Application:

The Role of Sandwich Biscuit Making Machines

The production of sandwich biscuits involves a precise and efficient process, and this is where sandwich biscuit maker machines come into play. These machines are designed to automate and streamline various stages of production, from dough mixing and shaping to filling and sandwiching. Here's an insight into their key features and functions:- Dough Mixing: Sandwich biscuit making machines often start with a dough mixing stage. They mix the ingredients to create the biscuit dough, ensuring consistency and quality.

- Biscuit Forming: The machine then shapes the dough into individual biscuit layers. It can create a range of shapes and sizes, depending on the desired end product.

- Baking: Once formed, the biscuit layers are baked to perfection. Baking parameters such as temperature and time are carefully controlled to achieve the desired crispness and color.

- Filling Application: After baking, the creamy filling is precisely applied to one of the biscuit layers. The machine ensures an even distribution of the filling, maintaining the desired ratio of biscuit to filling.

- Sandwiching: The second biscuit layer is placed on top of the filling-covered layer, creating the iconic sandwich biscuit structure.

- Cooling and Setting: The freshly sandwiched biscuits are then cooled to set the filling, ensuring a stable and consistent product.

- Packaging: Finally, the sandwich biscuits are packaged for distribution, ensuring they remain fresh and delicious until they reach consumers.

What the sandwich biscuit machine supplier can provide:

Product quality: Keep improving, all parts are made of high-quality materials.

After-sales service: installation and commissioning, maintenance services are provided for failures caused by non-human factors during the one-year warranty period.

In-sale service: arrange machine testing, take customers to visit factories, etc.

Variety of models: According to different user needs, our factory has different models to choose from.

Technical Data

| Model | GG |

| Capacity | 100KG/H |

| Voltage | 380 V |

| Materials | Stainless Steel |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language