Products

Product Introduction

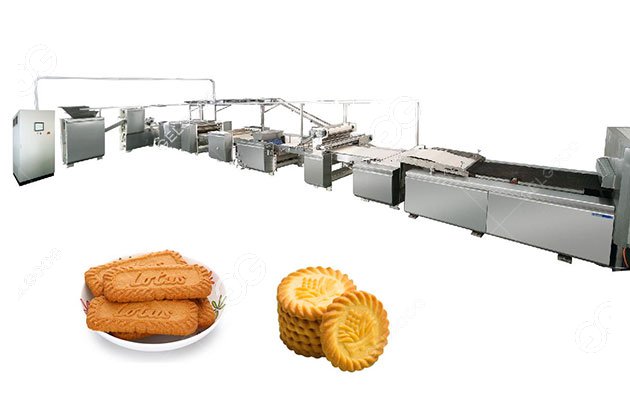

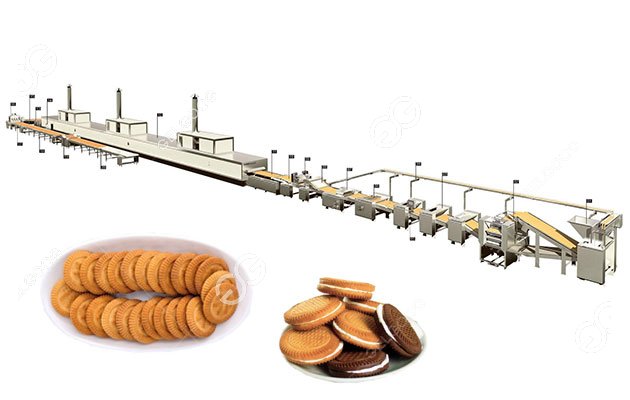

Industrial soft biscuit production line is used to produce soft biscuits in large quantities. The lowest production capacity is 100 kg per hour, and the highest production capacity is 1200 kg per hour.

The production line can produce different types of soft biscuits, patterns, shapes, sizes all can be customized according to your requirements. One machine with multiple functions helps you save investment costs.

Soft Biscuit Processing Technology:

1. Ingredients:

Flour: The primary ingredient, which provides structure and texture.

Sugar: Sweetens the biscuits and contributes to texture.

Fat: Usually butter or margarine, for tenderness and flavor.

Eggs: Provide moisture and structure.

Leavening Agent: Often baking powder or baking soda to help the biscuits rise slightly.

Liquid: Typically milk or water to bring the dough together.

Flavorings: Vanilla extract, spices, or other flavorings for taste.

Inclusions: Chocolate chips, nuts, dried fruits, etc., for added flavor and texture.

2. Processing Steps of Industrial Biscuit Production Line:

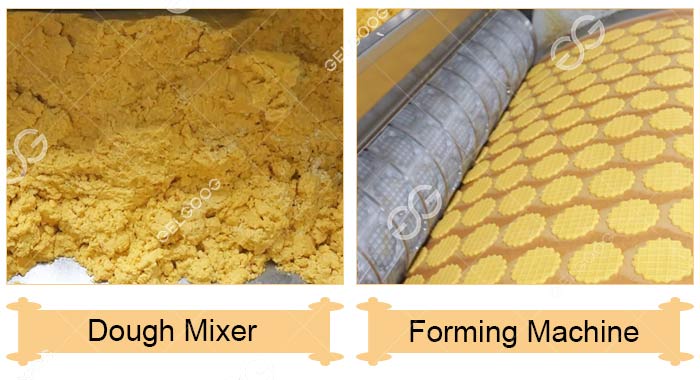

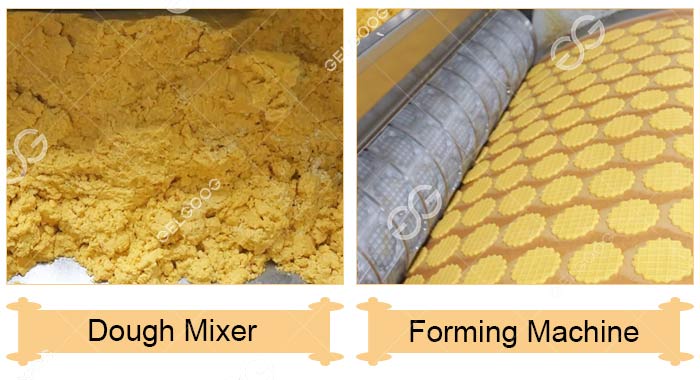

Mixing: Combine flour, sugar and leavening agents, oil, seasonings and other ingredients in a large mixer machine in order. Stir until these ingredients form a fluffy mass.

Shaping: After mixing, the large dough is cut into small pieces, and then conveyed to the feeding port, and the mold rolls the dough into soft biscuits of the same size. The pattern and size of the biscuit is determined by the mold.

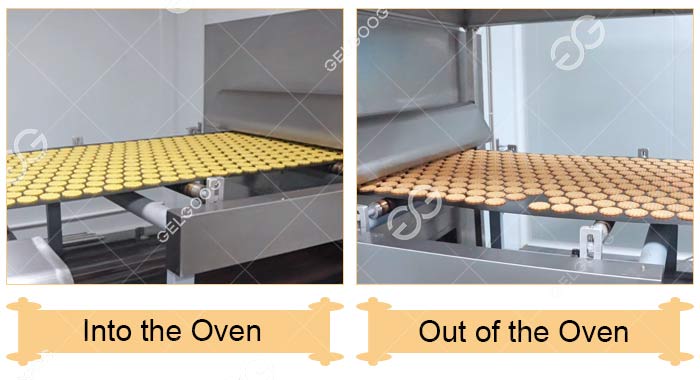

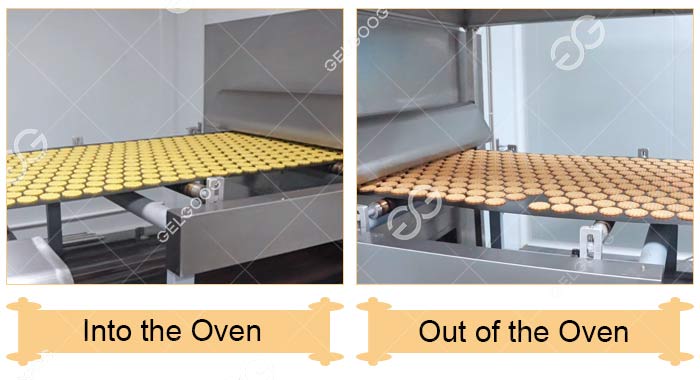

Baking: After entering the tunnel oven, the biscuits will pass through different temperature zones, and the biscuits will be baked to the ideal color and taste.

Cooling: After baking, the biscuits are cooled through a long conveyor belt, and during the cooling process, they pass through oil sprayers, powder spreading devices, etc.

Packaging: Once the biscuits have cooled to about 30 degrees, the soft biscuits are packaged for distribution. They are usually sealed in airtight containers or wrapped in plastic to retain moisture and freshness.

Soft Biscuit Molds Pictures:

Advantages of Soft Biscuit Production Line

- This equipment can not only produce unique double-layer sandwich biscuits, but also produce a variety of crispy biscuits. And it is a new flavor of biscuits that is well combined with the local flavor diet.

- The soft biscuit processing line has the quality of first-tier brands, but the price is only two-thirds of that of first-tier brands, which is very cost-effective.

- The operation of the biscuit production line is stable and efficient, and the qualified rate of biscuit production can reach more than 95%.

- Possess the planning ability of the whole line plan, and can provide a full range of production guidance (including the planning and layout of the production line workshop; research and development of corresponding product formulas according to product requirements; training of operators, etc.).

- This automatic biscuit line can be modified and upgraded for your existing production line to meet your needs.

Soft Biscuit Processing Line Working Video

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language