Products

Product Introduction

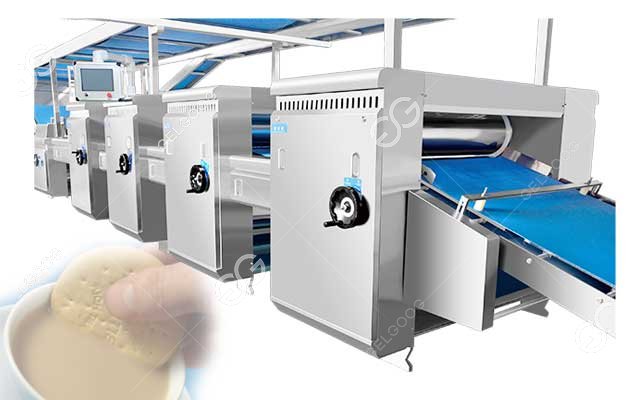

The company focuses on providing tea biscuits manufacturing plant, which can produce tea biscuits, rich tea in batches. To meet the ever-changing tea biscuits market and the diverse needs of biscuit manufacturers.

In order to meet the needs of food processing factories of different scale, the equipment developed by the company has different models(different production capacities), but all other functions are the same.

In order to meet the needs of food processing factories of different scale, the equipment developed by the company has different models(different production capacities), but all other functions are the same.

Features of Tea Biscuits Manufacturing Plant

- Customized production capabilities: The design of the equipment is flexible and can be adapted to different tea biscuit production scales to meet your customized needs. The plant is adjustable and can produce 300 to 1000 kilograms of tea biscuits per hour.

- Intelligent control system: Our tea biscuits plant is equipped with PLC display screen and advanced temperature control system to realize automated production and improve the production efficiency of biscuits.

- Full set of process flow: The machine covers all aspects of tea biscuit manufacturing, including mixing, forming, baking, cooling, packaging and other processes, ensuring the quality and taste of tea biscuits.

- High-efficiency and energy-saving design: Our equipment adopts advanced energy-saving technology to minimize energy consumption, which is not only beneficial to environmental protection, but also helps biscuit manufacturers reduce production costs.

- Easy maintenance and maintenance: The structure of the equipment is simple and independent. When problems are discovered, the equipment can be quickly located and repaired. Reduce production downtime due to equipment failure.

Advantages of Automatic Tea Biscuits Plant

- Product differentiation: Customized production lines enable biscuit manufacturers to produce tea biscuits with unique flavors and shapes, thereby achieving product differentiation in a highly competitive market.

- Market Agility: Our tea biscuits manufacturing facility strives to provide flexibility and agility to adapt to changes in market demand. Biscuit manufacturers can adjust production lines at any time according to different market trends.

- Cost-Effectiveness: Our equipment is designed to increase production efficiency and reduce production costs, allowing biscuit manufacturers to provide high-quality tea biscuits more competitively.

- Technical support and training: We provide customers with comprehensive technical support and training to ensure that they can fully understand and operate our equipment to achieve the best production results.

- Reliable Delivery and After-Sales Service: Based on its large and experienced team, we at Gelgoog Company are committed to providing reliable equipment delivery and excellent after-sales service to ensure long-term customer satisfaction.

Video of Tea Biscuits Manufacturing Plant

Our tea biscuits production line is a highly customized solution that provides biscuit manufacturers with flexibility, efficiency and innovation. The production line has become an ideal choice for the tea biscuits and other biscuits market with its multiple features and advantages, meeting the production needs of different manufacturers. We welcome biscuit manufacturers to come for consultation and discuss how to upgrade and differentiate production through our production lines.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language