Products

Product Introduction

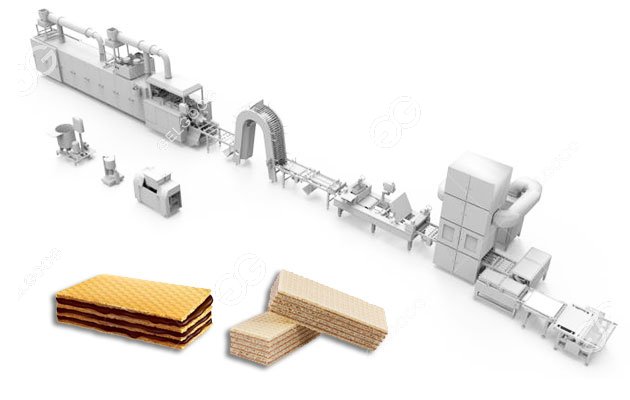

The automatic wafer biscuit production line has 27 molds, 39 molds, 45 molds, 51 molds and 75 molds, which are specially used to produce high-quality wafer biscuits with high automation and high efficiency.

This production line is a new generation product developed and designed based on the advanced structure of similar products at home and abroad, using electric heating as the heat source. Exclusively developed in China, it has successfully solved the problems of high production cost and large color difference on the surface of wafer biscuits in the production of wafer biscuits.

This production line is a new generation product developed and designed based on the advanced structure of similar products at home and abroad, using electric heating as the heat source. Exclusively developed in China, it has successfully solved the problems of high production cost and large color difference on the surface of wafer biscuits in the production of wafer biscuits.

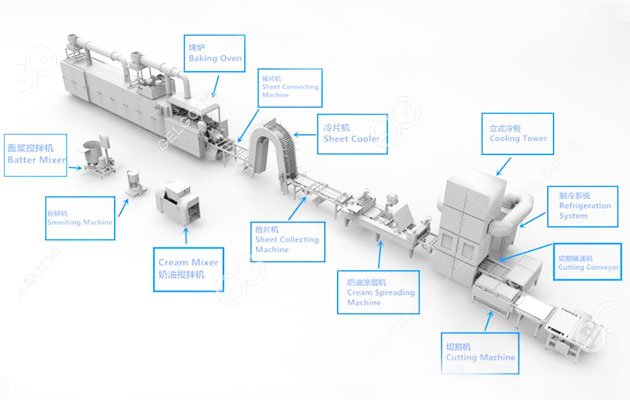

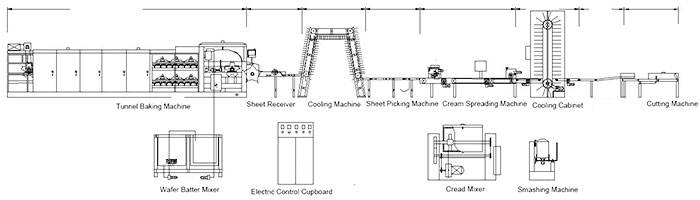

Components of Industrial Wafer Biscuit Production Line:

This line consists of mixing machine, continuous tunnel oven, picking machine, cooling machine, cream spreaing machine, cutting machine, coating machine, packaging machine, etc. It has a compact structure and good stability. It is an ideal equipment for the biscuit food industry.

Wafer Biscuit Manufacturing Process:

Raw material preparation→batter making→baking in the oven→cleaning→picking→cooling→cream coating→wafer sheet cutting→crush the wafer biscuits→packing.

Video of Automatic Wafer Biscuit Production Line:

Video of Automatic Wafer Biscuit Production Line:

Features of Wafer Production Line:

1. It is easy to operate, safe and reliable, the wafers are flat, uniform in thickness, and beautiful in color.

2. The whole machine is made of high-quality stainless steel, which is anti-corrosion and anti-rust.

3. This line can be combined arbitrarily according to the user's site requirements and biscuit process requirements.

4. The continuous tunnel oven has gas heating and electric heating options.

5. Automatic wafer biscuit production line with high efficiency, strong automation, and effective labor cost savings.

Founded in 2010, the company is mainly engaged in the design, research and development, manufacturing, sales and service of cookie production lines, crisp and tough biscuit lines, wafer production lines, sandwich biscuit lines, baking ovens, food packaging machines, etc. After more than 10 years of development, the output and quality are excellent, the price is affordable, and the products are sold all over the world.

Founded in 2010, the company is mainly engaged in the design, research and development, manufacturing, sales and service of cookie production lines, crisp and tough biscuit lines, wafer production lines, sandwich biscuit lines, baking ovens, food packaging machines, etc. After more than 10 years of development, the output and quality are excellent, the price is affordable, and the products are sold all over the world.

Technical Data

| name | quantity | |

| 1 | Flat automatic gas heating oven | 1 |

| 2 | Splicing machine | 1 |

| 3 | Wafer sheet cooling machine | 1 |

| 4 | Cream spreading machine | 1 |

| 5 | Wafer cutting machine | 1 |

| 6 | Blender Machine | 1 |

| 7 | Cream mixer | 1 |

| 8 | Swashing Machine | 1 |

| 9 | Air compressor | 1 |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language