Products

Product Introduction

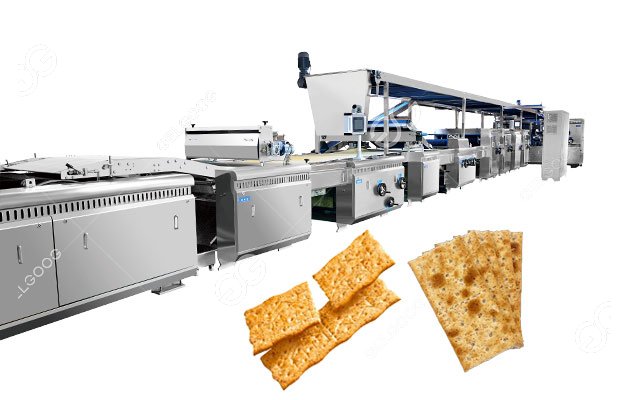

The automatic wheat cracker production line is a full solution, integrating raw material processing, molding, baking, cooling, and packaging. It adopts advanced food processing technology and fully automated operation, providing manufacturers with a one-stop solution.

In the fast-paced snack manufacturing industry, the development of such efficient equipment has received widespread acclaim. We are proud to launch the wheat cracker solution to help companies improve efficiency.

Features of Wheat Cracker Line

- Intelligent adjustment, constant quality: Our machines are equipped with advanced PLC control systems, which can intelligently fine-tune the baking temperature and time according to product requirements to ensure that the color and taste of each batch of wheat crackers are uniform and consistent, locking in freshness.

- Various forms, strong market adaptability: The automatic wheat cracker production line has high design flexibility, and can produce a variety of cracker forms and sizes by quickly switching molds, seamlessly connecting to market trends, whether classic shapes or trendy innovations, they can be presented one by one.

- Equal emphasis on efficiency and environmental friendliness: Combining efficient energy management systems and environmental control technologies, the production line can significantly reduce energy consumption while ensuring high-speed output, and is equipped with environmentally friendly treatment modules to achieve harmonious coexistence between production and nature.

- Food safety, starting from the source: from the high-standard material selection of material contact surfaces to the fully closed operating environment, combined with regular deep cleaning and disinfection procedures, strictly abide by international food safety standards, so that consumers can eat with confidence.

- Easy maintenance, and intelligent early warning: The integrated fault prediction and diagnosis system can detect and prompt potential problems in advance, reduce downtime and maintenance time, and combine with simple maintenance design to ensure stable and efficient operation of the production line.

Video of Wheat Cracker Processing Line

Advantages of Automatic wheat cracker production line

•Increase production capacity: Compared with semi-automatic production mode, the automatic production line significantly shortens the production cycle and increases production capacity several times.

•Reduce costs: Manpower demand is greatly reduced, while precise raw material control reduces waste, and long-term operating costs are significantly reduced.

•Ensure quality: The wheat cracker line strictly monitors every step from raw materials to finished products to ensure excellent and uniform product quality.

•Innovative and flexible: Easy-to-adjust wheat cracker processing line settings facilitate rapid response to market changes, development of new products, and meeting the growing personalized needs of consumers.

Widely Application

- Snack food industry: Provide supermarkets and convenience stores with a wide variety of wheat crackers on the shelves, becoming a new favorite for daily snacks.

- Baking industry: As a specialty snack in bakeries and coffee shops, paired with tea and coffee, it enhances customer experience.

- Catering supply chain: As a snack for hotel and airline meals, it enriches menu options.

- Healthy food market: Launch low-fat, sugar-free and other healthy versions to meet the needs of specific consumer groups.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language