Products

Product Introduction

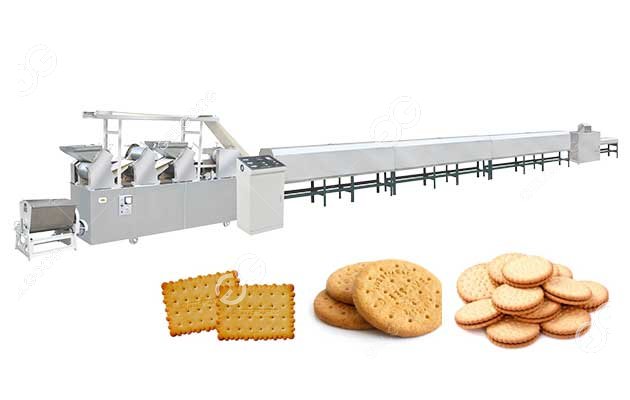

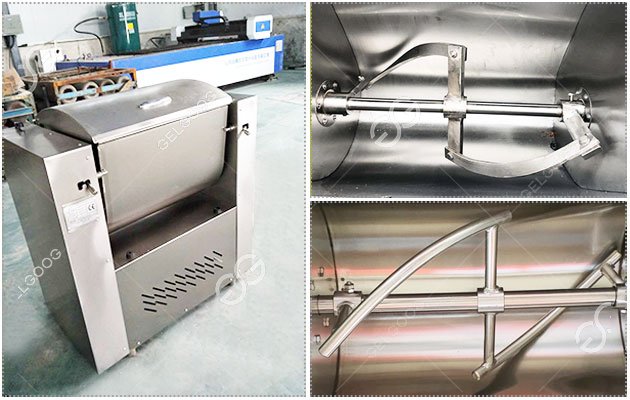

The biscuit dough mixing machine produced in the factory simulates the principle of manual mixing, so that the gluten network is formed quickly, and the processed dough is smooth, good elasticity. Usually used in biscuit production line and other flour products industries.

The Working Principle of Horizontal Dough Mixer Machine

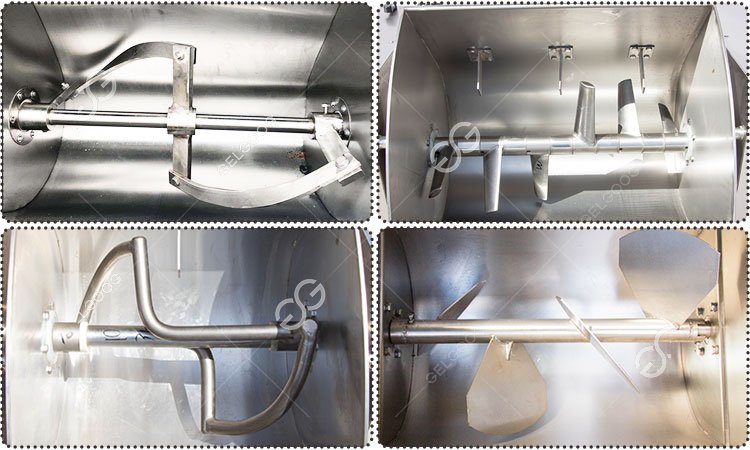

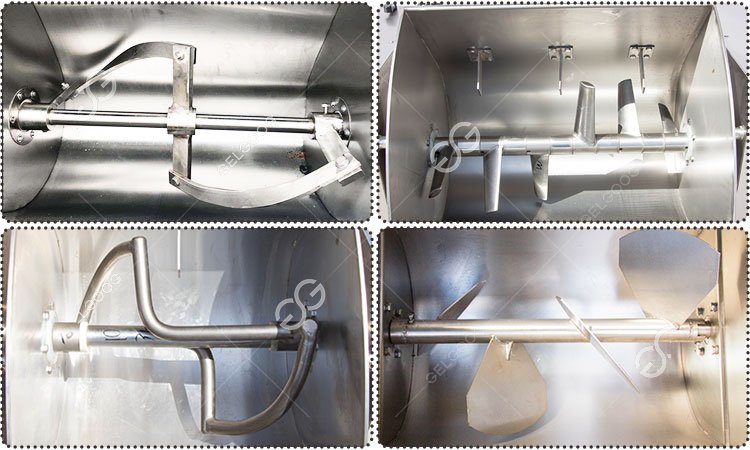

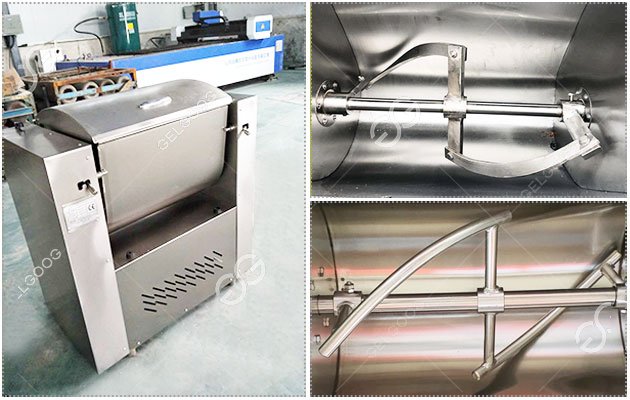

The screw agitator is driven by the transmission device to rotate in the mixing cylinder, and the mixing cylinder is driven by the transmission device to rotate at a constant speed. Flour is continuously pushed, pulled, kneaded, and pressed, and after uniform hydration, it expands gluten and becomes a dough with a certain degree of elasticity.

Performance and Characteristics of Automatic Dough Mixing Machine:

- The main body of the machine is made of high-quality stainless steel, and it is safe and hygienic in contact with food.

- With a unique structure, it is more convenient and easy to replace the seals and bearings of the machine.

- Biscuit dough mixing machine adopts PLC control with strong functions, and the time can be set according to different processes.

- This equipment adopts the double-acting method of mixing rod and bucket to mix the dough, which will not hurt the gluten.

- The bowl can automatically rise and fall. It adopts one-key operation, which is more convenient and quicker and improves work efficiency.

Commercial Dough Mixing Machine Instructions

1. After the power is turned on and the machine runs without abnormality, the next step can be performed.

2. Pour flour, water and additives into the kneading bucket one after another, close the lid, turn on the switch, and the mixer starts to rotate forward.

3. Generally, run continuously for 6-10 minutes, the dough is mixed, and the machine stops. Pull the handle of the tipping bucket again to turn the bucket upside down, reset the handle, and the block is stressed. After the bucket is fixed, flip the switch and the dough will be thrown out.

Precautions for Using the Biscuit Dough Mixer Machine:

1. Before starting the machine, check the equipment and circuit conditions carefully, and only after confirming that it is correct, the machine can be used.

2. The reversal time should not be too long. After the tipping bucket is tilted in place, the knife should be used to break the dough, and the hand must leave the bucket during the forward and reverse rotation.

3. When the biscuit dough mixing machine is running, the operator cannot put his hands in the bucket.

4. The operator should fill the lubricating hole with lubricating oil every day; insist on cleaning up every day to keep the machine clean.

5. When you need to clean after mixing the dough, check whether the power is off before proceeding to the next step.

6. If abnormal operation of the equipment is found, turn off the power immediately and notify the support department for maintenance.

Technical Data

| Model | GGMH15S | GGMH25S |

| Capacity(kg/h) | 150 | 250 |

| Power(kw) | 1.1 | 1.5 |

| Dimensions(mm) | 730*440*870 | 770*490*950 |

| Weight(kg) | 100 | 110 |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language