Products

Product Introduction

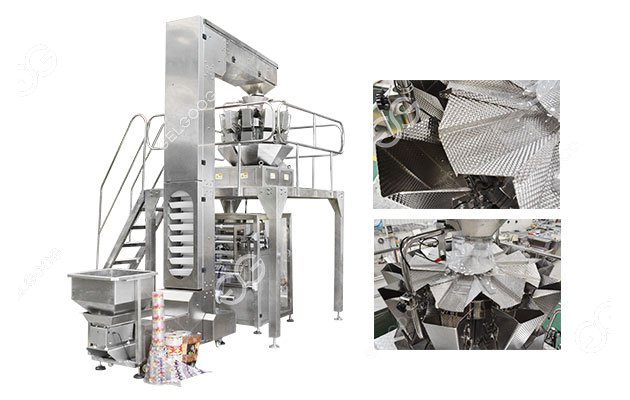

Small biscuit packing machine is suitable for weighing granular products such as candy, jelly, chips, peanuts, biscuits, chocolate, nuts, potato chips, pet food, frozen food, etc. Capable of packing at a rate of 15-80 bags per minute.

Multi-head weighing packaging machine is mainly composed of multi-head weighing machine, main packaging machine, z-type hoist, supporting platform and so on. With weighing, counting, positioning, measuring, feeding, blanking and safety, protection and other functions.

Multi-head weighing packaging machine is mainly composed of multi-head weighing machine, main packaging machine, z-type hoist, supporting platform and so on. With weighing, counting, positioning, measuring, feeding, blanking and safety, protection and other functions.

Technical Features

1. The biscuit packing machine is controlled by dual frequency converters, the bag length can be set and cut immediately, and the air travel can be adjusted, which can be done in one step, saving time and film.

2. High-sensitivity photoelectric eye color code, digitally input sealing and cutting position, so that the sealing and cutting position is more accurate.

3. Human-machine interface, parameter setting is convenient and quick. In addition to Chinese or English, the parameter panel can also use other languages, such as French, Spanish, Arabic, Russian, German, etc.

4. The packing machine can pack different products, and the measurement is accurate, the speed is fast, and it can be adjusted according to needs.

5. With fault self-diagnosis function, it is clear at a glance when the machine fails. Targeted maintenance.

6. The industrial biscuit packer machine adopts temperature PID control, which is suitable for various packaging materials.

Application Products

This small biscuit packing machine is mainly used for packing granular products: such as biscuits, popcorn, potato chips, coated peanuts, nuts, chocolate chips, chips, cookies, cupcakes, sunflower seeds, mini cones, bread, frozen dumplings, spring rolls and other foods. Condiments such as salt, sugar, rice, rock sugar, etc. can also be packaged. There are other non-food laundry detergents, desiccants, etc.

Workflow of the Packaging Machine is as follows:

1. Install the corresponding packaging film on the packaging machine according to different product requirements.

2. According to the film width and product height, adjust the packaging mouth, and start the packaging machine after the rectification is completed.

3. Adjust the speed of the conveyor belt of the packaging machine according to the speed of the product.

4. Put the product to be packaged on the conveyor belt, and transfer it into the packaging port.

5. The product passes through the packing mouth, weighs and seals.

Company Services:

The quality guarantee period of the machine is 1 year. Except for wearing parts (knives, belts, horizontal and vertical heating pipes, etc.), most parts (PLC, servo controller, servo motor, touch screen, cylinder) can be replaced free of charge.

1. Welcome to study in our factory.

2. The machine is easy to operate and provides installation steps and videos.

Technical Data

| Model | GG-LK420 |

| Film width | max 420mm |

| Bag width | 80-200mm |

| Bag length | 50-300mm |

| Packing speed | 15-80bags/min |

| Packing range | 150-1500ml |

| Film thickness | 0.04-0.10mm |

| Power | 2.5kw/220v 50-60Hz |

| Machine size | 1400*970*1700mm |

| Machine weight | 450kg |

| Air consumption | 0.4m³/min 0.6mpa |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language