Products

Introduction to the product

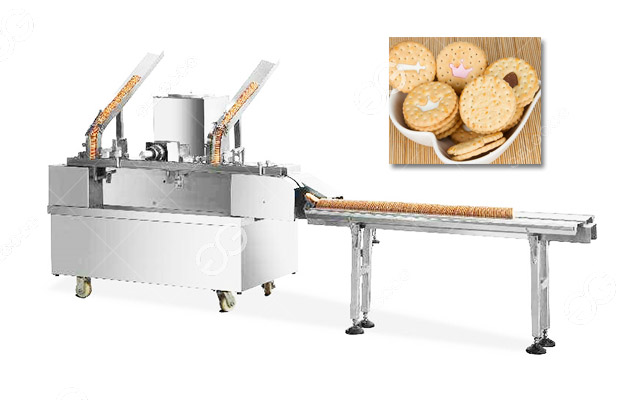

Cookie cream sandwich machine is one of the main equipments of biscuit factory. It is specially designed for the production of cream sandwich cookies, mass production and large production capacity.

The equipment has high compatibility and is suitable for various sandwich products such as hard biscuits, soft biscuits, cookies and so on. It is especially suitable for high-precision cream or jam filling, and is an ideal choice for large biscuit processing companies.

Structural composition of the equipment

- Conveying system: The cookie cream sandwich machine adopts food grade stainless steel conveyor belt, which is divided into two layers, transporting the lower and upper layers of cookies respectively and transporting them accurately and synchronously.

- Sandwich filling device: The core is high-precision gear pump or piston filling system, which supports quantitative extrusion of sandwich materials with different viscosity, such as cream and jam.

- Alignment and pressing mechanism: equipped with photoelectric sensors and servo motors to ensure precise alignment of the upper and lower layers of biscuits and complete soft pressing with adjustable pressure device.

- Control system: The cookie sandwich machine integrates PLC and touch screen interface, and supports parameter pre-setting, fault alarm and production data recording.

- Body: all stainless steel, meets food hygiene requirements, compact structure and easy to clean and maintain.

Five Features of a Cookie Sandwich Machine

- Wide applicability: It can process square, round and special-shaped biscuits, and is also suitable for various sandwich materials such as cream, chocolate sauce, pectin, etc.

- Food Grade Material: The contact surface of the sandwich machine is made of food grade 304 stainless steel. It is corrosion resistant, easy to clean, and meets FDA and EU standards for food equipment.

- Intelligent operation: Based on the principle of continuous filling, the cookie sandwich volume is ±1% error through closed loop control to avoid empty filling or overfilling.

- Efficient compatibility: The biscuit sandwich machine can be connected with tunnel oven, turning machine and packing line, supporting an adjustable range of 2000-12000 cream sandwiches per hour.

- Flexible adjustment function: Sandwich thickness(0.5-5mm), filling speed and pressing force can be adjusted by one touch on the touch screen to meet the production needs of different categories.

How to use cookie cream sandwich maker?

- Preparation: Clean the equipment and install the specified sandwich hopper, adjust the width of the guide plate and the speed of the conveyor belt according to the size of the biscuits.

- Parameter setting: Set the number of sandwiches, pressing pressure and production speed via touch screen and call up the pre-stored formula to improve efficiency.

- Start working: Turn on the conveyor belt, filling pump and pressing module in sequence, and the cookie sandwich making machine will automatically complete cookie loading, sandwich injection and finished product dispensing.

- Real-time monitoring: Ensure the uniform distribution of sandwich through the viewing window or sensor data, and process abnormal alarms (such as lack of material or misalignment) in time.

- Cleaning and maintenance: Run CIP cleaning program after production, disassemble the moving parts of the cookie sandwich making machine for deep disinfection, and lubricate the transmission parts regularly.

Technical data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language